Dished and flanged heads

DVAI is the French specialist manufacturer of tank heads. By flanging or spinning, DVAI proposes all the range of tank bottoms from diameter 20mm to diameter 4500mm, from thickness 1mm to 25mm, in all grades of austenitic stainless steel (304L, 316L, 321, 316Ti and 904L stainless steel), refractory stainless steel (310S) and duplex (UR35N, UR45N), aluminum, copper, titanium and nickel alloys. DVAI can offer you tanks in both stainless steel and black steel. For some dimensions, it may be necessary to perform a heat treatment.

DVAI can also provide you polished tank heads, and make openings for nozzles.

Different standards

DVAI can provide you any type of tank head while following NFE81 100 norm : GRC (Large Knuckle Radius – DIN28011 – NFE81102), PRC (Small Knuckle Radius NFE81101), fonds MRC (Medium Knuckle Radius NFE81104) and ELL (Elliptical). All these types can be used to manufacture a complete stainless steel tank.

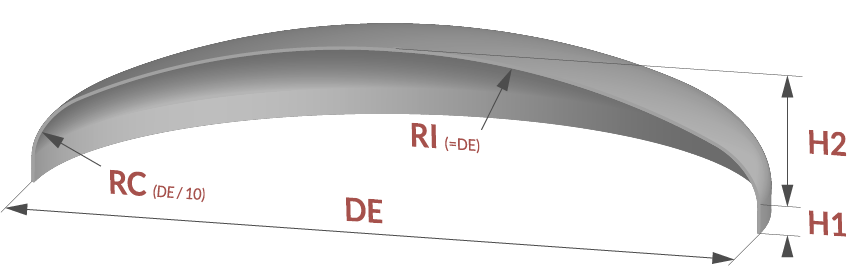

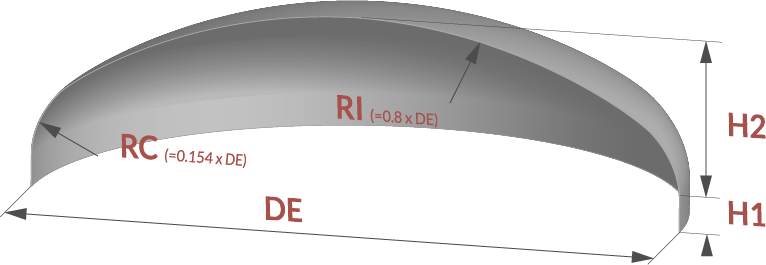

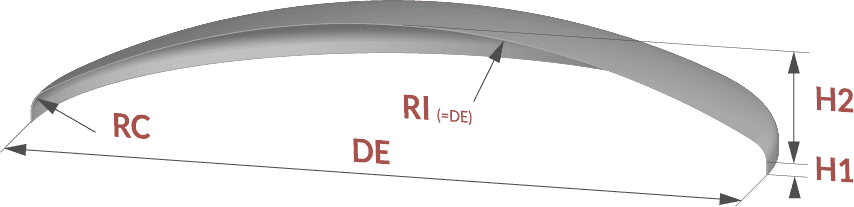

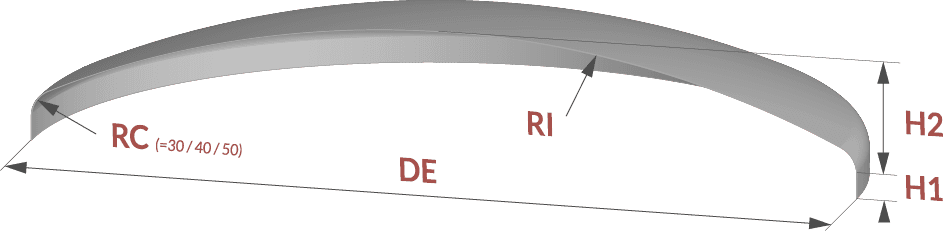

Tank head characteristics

DE: external diameter

E: nominal thickness

RI: spherical radius

RC: knuckle radius

H2: theoretical internal arrow

H1: straight edge height

Dished heads dimensions

The dimensions of your tank (diameter, height) are often determined by its useful volume, it is then necessary to know the volume in liters of heads to determine the volume of the shell. As part of the boilermaking, to achieve this first step in the design of your tank, you can know the volume of our heads through our chart below :

If you can not find the appropriate size, contact us for further information.

NFE 81-100 tank bottoms

A dished head is constituted by a spherical cap, a toric element and a cylinder-shaped edge.

- PRC : Small knuckle radius head NFE 81-101 or Shallow head

- MRC : Medium knuckle radius head NFE 81-104

- GRC : Large knuckle radius head NFE 81-102 or Klöpper head, DIN28011

- Elliptical head NFE 81-103 or Korbbogen head, DIN28013

Tolerances according to NFE 81-100

– Expansion length tolerances:

Case of MRC and PRC:

– If De <= 2000: 0/+6 mm – If De > 2000: 0/+10 mm

Case of GRC and ELL:

– If De <= 6000: +/- 0.003 x De – If De > 6000: +/- 0.001 x De

– Thickness tolerances: minimal thickness = 85% of nominal thickness

– Depth tolerances h1 + h2:

Depth <= 6mm : +/- 0.0075 x De Depth > 6mm : +/- 0.01 x De